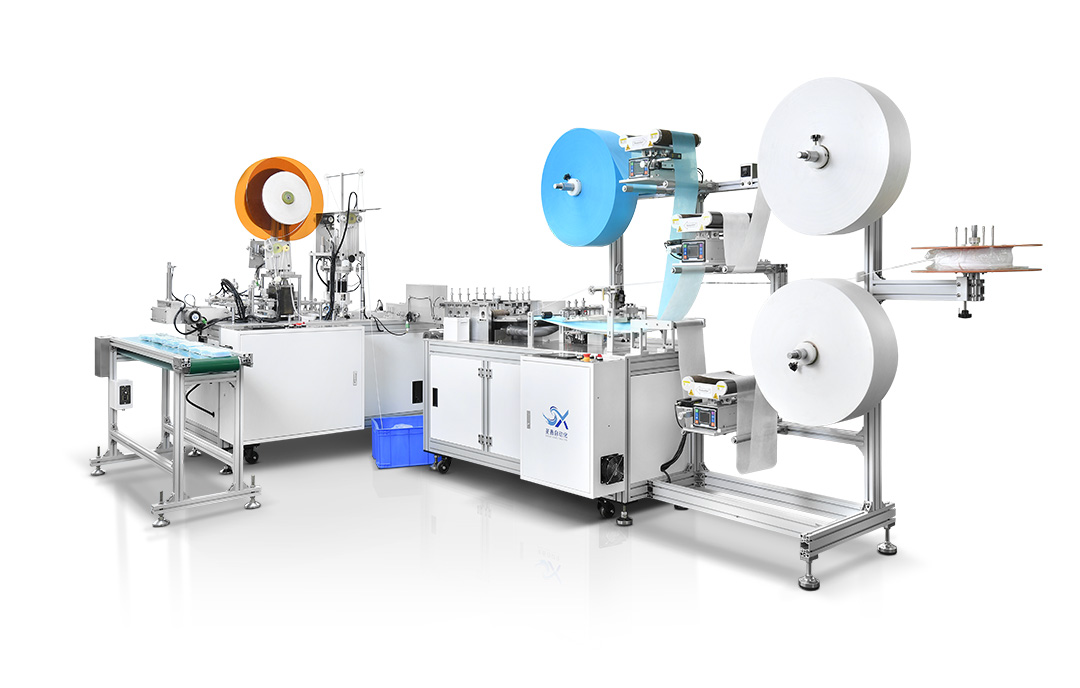

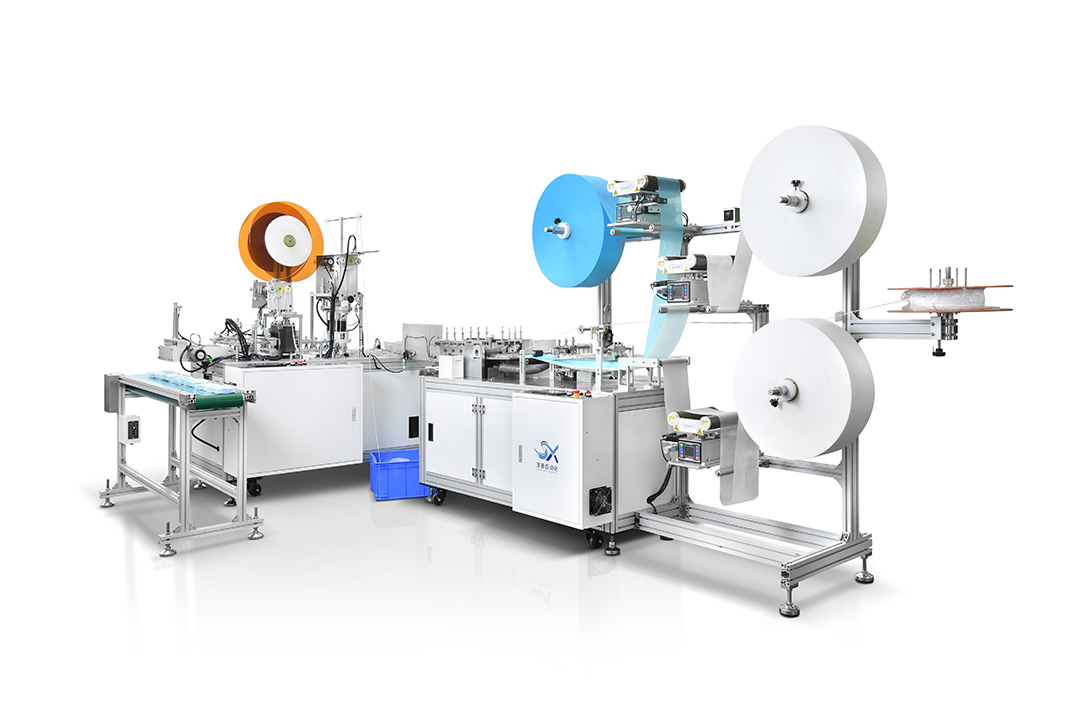

Application:

This model is the latest developed fully automatic production line for flat inner ear masks, including automatic raw material conveying/cutting of nose bridge strips/mask edge welding/folding/ultrasonic fusion/forming cutting/flipping/ear band welding/edge wrapping welding and cutting/automatic finished product delivery, etc. The entire production process from raw materials to mask products is fully automated.

Features:

1. High stability and low failure rate;

2. PLC control and touch screen human-machine interface, simple and convenient operation;

3. Automatic tension and correction control of raw materials to ensure balanced tension and automatic correction of fabric position;

Photoelectric detection of raw materials to reduce material waste, while sound control alarm prompts and shutdown;

Product Display:

Finished product display:

Customer Service 1

Customer Service 1